The goal of this post is to outline the general behavior of our rod rotator program with example code for demonstration. It is not to go through everything line-by-line. The project was originally developed by another postdoc, Oscar Martinez. It has been updated, refactored, expanded upon, and maintained by me. For the complete code, see here.

The Problem

Studying the temperature-dependent kinetics of charged metal and metal-oxide nanoclusters requires unique instrumentation. Reliably creating charged metal and metal-oxide nanoclusters can be a challenge. Thanks to Nobel laureate Richard Smalley's game-changing laser vaporization cluster source, a wide variety of metal and metal oxide clusters can be formed by ablating a moving metal target with a high-power laser. In order to couple to existing instrumentation, this meant designing our own.

The source itself involves a pulsed gas flow over a metal rod that is being ablated by a laser. The gas expands into the vacuum chamber cooling the metal particles, allowing them to cluster. The unique challenge inherent to the metal target is providing a fresh spot of metal for each laser pulse (approximately), so what's needed is motion. We could rotate the metal rod, but rotation can only provide a limited number of new "spots." What we really need is rotation and up/down translation of the rod. Further, different metals have different conditions that allow for cluster formation, including rod rotation speed.

The Solution

Our design involves a stepper motor that turns a threaded 1/4-80 rod connected to a magnetic vacuum feedthrough, on the other side of which is the metal rod target. Together, the stepper motor and threaded rod allow for rotation and translation of the metal target at 80 rotations per inch of vertical travel.

We will need variable rotation and translation speed controlled by pulsing the stepper motor at different frequencies, the ability to reverse translation direction, and it's probably a good idea to add some limits on translation to prevent the metal rod from translating too far up or down and damaging the apparatus.

Parts

- 1 x Stepper Motor

- 1 x Raspberry Pi 3

- 1 x Half Breadboard

- 2 x Limit Switches

- 1 x LED

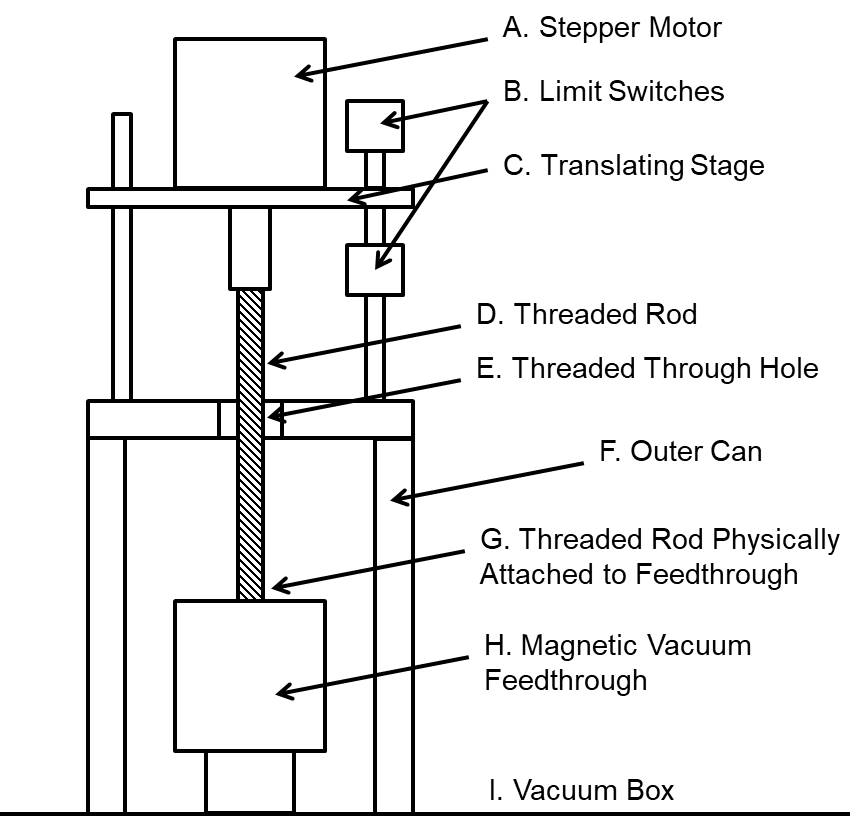

A diagram of our current solution (Raspberry Pi and circuit not pictured):

The stepper motor (A) spins the threaded rod (D), which physically connected to a magnetic feedthrough (H) that rotates the metal rod inside the vacuum box (I). The stepper motor is connected to the Raspberry Pi GPIOs and rests on a vertically translating stage (C), whose distance of travel is defined by the limit switches (B), which are also connected to the Raspberry Pi. The translating stage itself moves the entire stepper motor up and down because of the threaded through hole in the outer can (F).

How can we control all of this? Using a Raspberry Pi 3 and touchscreen mounted to the side of the instrument.

Software and Control Hardware Design

For this project, I chose Python and the PyQt5 GUI framework to create an intuitive touch application to control the rotation speed, total distance of travel, and alert the user to a triggered limit switch. Python was chosen for its relatively quick development time readability, the maturity of the PyQt5/Qt framework, and the author's familiarity.

Developing and customizing the GUI is as easy as "click and drag" with PyQt5 Designer.

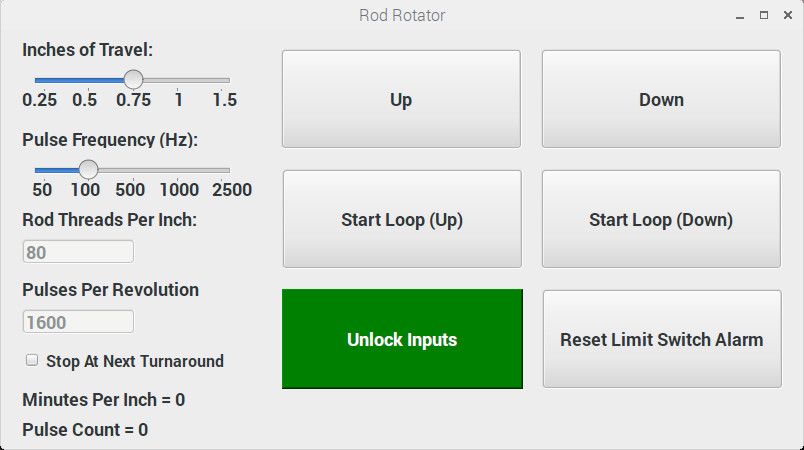

The current rod rotator GUI:

The resulting interface has all of the inputs necessary to control the direction, speed, and stepper motor pulse frequency.

Let's create a new .py script with the necessary PyQt5 libraries and a Window class that will serve as the main window:

import sys

import RPi.GPIO as GPIO

from PyQt5 import QtWidgets

from PyQt5.QtWidgets import (QWidget, QApplication, QLabel, qApp,

QLineEdit, QPushButton, QGridLayout)

import PyQt5.QtCore as QtCore

from PyQt5.QtCore import QPoint, pyqtSignal, pyqtSlot, Qt

import PyQt5.QtGui as QtGui

# GUI is imported from MTZv3_ui.py which needs to be in the same directory

from MTZv3_ui import Ui_Form as Main_Ui

class Window(QWidget):

def __init__(self):

super().__init__()

# Setup the UI

self.ui = Main_Ui()

self.ui.setupUi(self)

# When widget is run from terminal:

if __name__ == "__main__":

app = QApplication(sys.argv)

window = Window()

window.show()

sys.exit(app.exec_())How do we control the stepper motor?

Basically, what inputs does the stepper motor need?

The stepper motor needs an input of 3.3 V for each pulse and a separate 3.3 V input if it is to rotate in the reverse direction. Additionally, our program must know the pulses per revolution specified by the motor (this is variable on our motor, hence the input box).

So, let's add the pinouts and program states:

class Window(QWidget):

def __init__(self):

super().__init__()

# Setup the UI

self.ui = Main_Ui()

self.ui.setupUi(self)

### Pin Assignments ###

# Limit Switches:

self.forwardLimitPin = 12

self.backwardLimitPin = 19

# "PUL+"" on Servo Drive (white wire)

self.servoPulsePin = 17

# Pin 27, to "DIR+" on servo drive set to HIGH

# Setting this high and PUL+ high reverses stepper direction

self.reverseDirectionPin = 27

# Limit switch activated warning will be triggered on this input:

self.limitSwitchWarningPin = 5

self.buzzerPin = 23

# Running LED:

self.statusLEDPin = 18

### GPIO Setup ###

GPIO.setmode(GPIO.BCM)

GPIO.setwarnings(False)

GPIO.setup(self.forwardLimitPin, GPIO.IN)

GPIO.setup(self.backwardLimitPin, GPIO.IN)

GPIO.setup(self.servoPulsePin, GPIO.OUT)

GPIO.setup(self.reverseDirectionPin, GPIO.OUT)

GPIO.setup(self.limitSwitchWarningPin, GPIO.OUT)

GPIO.setup(self.buzzerPin, GPIO.OUT)

GPIO.setup(self.statusLEDPin, GPIO.OUT)

### Program Inital State ###

self._active = False

self.direction = None

self.screenLocked = False

self.activeButton = None

# Parameters for Travel:

# Minutes per Inch

self.MPI = None

# Total number of pulses

self.e = None

# Time between pulses

self.sec = None

# Limit switch backoff number of pulses

self.lsb = NoneWhen we want to move the stepper motor, all we need to do is set the servoPulsePin

(and reverseDirectionPin) HIGH at the frequency corresponding to the desired rotation speed

We'll use this function to achieve that:

# Function that processes a single stepper motor 'step'

# Called for each 'step' that the rod rotates

def pulseStepperMotorOnce(self, sec):

if not self.dev:

if self.direction == 'forward':

time.sleep(sec)

GPIO.output(self.servoPulsePin, GPIO.HIGH)

time.sleep(0.0001)

GPIO.output(self.servoPulsePin, GPIO.LOW)

elif self.direction == 'reverse':

time.sleep(sec)

GPIO.output(self.reverseDirectionPin,GPIO.HIGH)

GPIO.output(self.servoPulsePin, GPIO.HIGH)

time.sleep(0.0001)

GPIO.output(self.servoPulsePin, GPIO.LOW)

GPIO.output(self.reverseDirectionPin, GPIO.LOW)In order for us to know how long to wait between pulses of servoPulsePin HIGH

(the value of sec), we'll need to calculate it based on the other specified parameters.

Let's add a helper function to determine these values from the GUI inputs:

# Uses input field values to calculate the total pulses, total 'backoff',

# pulses, delay time

# Called immediately before rod begins rotating

def calculateParameters(self):

# From Frequency Input (Hz):

frequencyOptions = [50, 100, 500, 1000, 2500]

freqSliderVal = self.ui.frequencySlider.value()

# Frequency (Hz):

a = int(frequencyOptions[freqSliderVal])

# Threads per Inch:

b = int(self.ui.lineRodtpi.text())

# Pulses per revolution:

c = int(self.ui.linePulsePerRev.text())

# Distance of travel (inches):

lineDistanceOptions = [0.25, 0.5, 0.75, 1, 1.5]

distanceSliderVal = self.ui.lineDistanceSlider.value()

d = float(lineDistanceOptions[distanceSliderVal])

# limit switch backoff:

# 0.05 x thread/inch x pulse/rev

# ex. 0.05 x 80 x 1,600 = 6,400

lsb = 0.05 * b * c

# inches x (thread/ 1 inches) x pulses/rev

# ex. 1 x 80 x 1600 = 128,000 The total number of pulses

e = d * b * c

# Used as a wait time between pulses

sec = 1 / a

# Minutes per inch

MPI = (sec * c * (1 / 60) * b) + (0.0001 * b * c * (1 / 60))

return MPI, int(e), sec, int(lsb)Now that the pulse frequency, threads per inch (80), and distance of travel have been specified; and the total number of pulses, delay time between pulses, and minutes per inch has been calculated, let's look at the logic that handles the Up or Down direction:

def moveStepperMotor(self, MPI, e, sec, lsb, loop=False):

previousFreqValue = self.ui.frequencySlider.value()

for index in range(e):

if self.ui.frequencySlider.value() != previousFreqValue:

self.MPI, self.e, self.sec, self.lsb = self.calculateParameters()

self.ui.labelMinutesPerInch.setText("Minutes per inch = %.2f" %self.MPI)

previousFreqValue = self.ui.frequencySlider.value()

# Perform a single pulse of the stepper motor:

self.pulseStepperMotorOnce(self.sec)

self.ui.label.setText('Pulse Count = {0} / {1}'.format(index, self.e))

qApp.processEvents()

if loop:

if not self._active and not self.ui.cb_nextTurn.isChecked():

self.direction = None

break

elif not self._active:

self.direction = None

break

# Initiates rotation in one direction based on 'Up' or 'Down' button click

# Also stops rotation if it's already running and the same button is pressed

def handleRunOneDirection(self):

button = self.sender()

if not self._active and not self.activeButton:

button.setText('Stop')

self.activeButton = button

self._active = True

if button.objectName() == 'Down':

self.direction = 'forward'

elif button.objectName() == 'Up':

self.direction = 'reverse'

# Enables a thread that runs the function being passed

QtCore.QTimer.singleShot(0, lambda: self.runOneDirection(button))

# If a rotation loop is already running, it stops:

elif self._active and button == self.activeButton:

self._active = False

self.activeButton = None

# helper function that handles some of the required function calls at the

# beginning of a run. In production, this does more than what's included

# below.

def initiateRun(self):

MPI, e, sec, lsb = self.calculateParameters()

self.ui.labelMinutesPerInch.setText("Minutes per inch = %.2f" %MPI)

return MPI, e, sec, lsb

# Rotation loop. Terminates when total 'steps' is reached

def runOneDirection(self, button):

self.MPI, self.e, self.sec, self.lsb, blinkLED = self.initiateRun()

# from zero to 128,000 (for example)

self.moveStepperMotor(self.MPI, self.e, self.sec, self.lsb)

if button.objectName() == 'Down':

button.setText('Down')

elif button.objectName() == 'Up':

button.setText('Up')

self.resetStates(button)The program keeps track of the running state (self._active), the button used to

initiate rotation (self.button), and the current rotation direction (self.direction)

for a few different reasons. The first is to prevent the rotation behavior from being initiated

more than once simultaneously by pressing multiple buttons without stopping the prior rotation.

Second, it's so the limit switches are "direction-less". The motor will back off in the

opposite direction of travel regardless of how the limit switches are positioned before stopping.

Speaking of limit switches, why do we even need them?

We need them because the maximum distance of travel is dictated by the physical size of certain components that make up the mechanical rod rotator (e.g. the magnetic feedthrough and length of the threaded rod). Allowing the stepper motor to move endlessly in one direction would likely destroy the threads on the 1/4-80 rod and potentially damage the motor or feed through. Best to avoid that...

At this point in the program, we've already calculated the number of pulses to send to the motor

that will allow it to rotate in the opposite direction relative to the current direction of travel

when the limit switch is triggered (lsb in calculateParameters()).

Let's add a condition to moveStepperMotor() that checks for a limit switch trigger

and a function that handles the limit switch behavior:

# Checks to see if either limit switch is pressed. If pressed,

# backs off switch based on value of self.direction and returns True

# Renames button based on arguments

def triggeredLimitSwitch(self, lsb, sec):

# If motor hits either limit switch on GPIO 12 or 19:

if GPIO.input(self.forwardLimitPin) or GPIO.input(self.backwardLimitPin):

if self.direction == 'forward':

# Runs motor in reverse to back off the limit switch

for index in range(lsb):

time.sleep(sec)

GPIO.output(self.reverseDirectionPin, GPIO.HIGH)

GPIO.output(self.servoPulsePin, GPIO.HIGH)

time.sleep(0.0001)

GPIO.output(self.servoPulsePin, GPIO.LOW)

GPIO.output(self.reverseDirectionPin, GPIO.LOW)

elif self.direction == 'reverse':

# Runs motor forward to backoff the limit switch

for index in range(lsb):

time.sleep(sec)

GPIO.output(self.servoPulsePin, GPIO.HIGH)

time.sleep(0.0001)

GPIO.output(self.servoPulsePin, GPIO.LOW)

# Enables limit switch warning on LCD and outputs to LabVIEW

GPIO.output(self.limitSwitchWarningPin, GPIO.HIGH)

# Enables buzzer sound

GPIO.output(self.buzzerPin, GPIO.HIGH)

self.ui.ResetWarning.setStyleSheet("background-color: red; color: white; font-weight: bold;")

self._active = False

self.direction = None

return True

else:

return False

def moveStepperMotor(self, MPI, e, sec, lsb, loop=False):

previousFreqValue = self.ui.frequencySlider.value()

for index in range(e):

# ...

# Perform a single pulse of the stepper motor:

self.pulseStepperMotorOnce(sec)

# If it doesn't hit the limit switch:

if not self.triggeredLimitSwitch(lsb, sec):

self.ui.label.setText('Pulse Count = {0} / {1}'.format(index, e))

qApp.processEvents()

else:

self.direction = None

break

# ...Now the program will check for a HIGH signal on either self.forwardLimitPin or self.backwardLimitPin. If HIGH,

it will "back off" the limit switch in the opposite direction of travel, set a buzzer output pin HIGH, and

display a warning on the GUI.

The last aspect of the program that we need to add is a way to loop over both the "Up" and "Down" directions. It's not very useful to have the metal rod stop moving after a minute or so. We want it to rotate back and forth until stopped by a button press. So, we'll add an additional function to handle the looping behavior:

# Intiates forward rotation loop

def handleRunLoop(self):

button = self.sender()

if not self._active and not self.activeButton:

self._active = True

button.setText('Stop')

self.activeButton = button

if button.objectName() == 'UpLoop':

QtCore.QTimer.singleShot(0, lambda: self.runLoop('reverse', button))

elif button.objectName() == 'DownLoop':

QtCore.QTimer.singleShot(0, lambda: self.runLoop('forward', button))

elif self._active and not self.ui.cb_nextTurn.isChecked():

if button == self.activeButton:

self._active = False

self.activeButton = None

elif self._active and self.ui.cb_nextTurn.isChecked():

if button == self.activeButton:

button.setEnabled(False)

self._active = False

button.setText('Stopping...')

# Forward rotation loop. Alternates between forward and backward directions

def runLoop(self, startDirection, button):

self.MPI,self. e, self.sec, self.lsb = self.initiateRun()

while True:

# Forward part of loop

self.direction = startDirection

self.moveStepperMotor(self.MPI, self.e, self.sec, self.lsb, True)

if not self._active and self.ui.cb_nextTurn.isChecked():

self.direction = None

break

# Backward part of loop

if startDirection == 'forward':

self.direction = 'reverse'

elif startDirection == 'reverse':

self.direction = 'forward'

self.moveStepperMotor(self.MPI, self.e, self.sec, self.lsb, True)

if not self._active and self.ui.cb_nextTurn.isChecked():

self.direction = None

break

if not self._active:

self.direction = None

break

if button.objectName() == 'DownLoop':

button.setText('Start Loop (Down)')

elif button.objectName() == 'UpLoop':

button.setText('Start Loop (Up)')

self.ui.cb_nextTurn.setChecked(False)

self.resetStates(button)That's it! I omitted a few features that can be found in the full source code, but at this point, you should have a good idea of the functionality of our Raspberry Pi driven metal rod rotator and be able to adapt it to similar applications.